“A Manufacturing Remnant Is Not Shown” – GIA Report

A laser manufacturing remnant on a polished facet surface.

I know most consumers will be surprised and worried when they find this unfamiliar looking comment stated in a GIA report. However, the statement “a manufacturing remnant is not shown” sounds a lot worse than it really is in real life.

Did you know that this comment is a recent addition to GIA’s clarity grading system? With more and more laser cutting tools being used in modern manufacturing, markings made (remnants) during the cutting process can sometimes be left on a finished diamond.

In the early days, massive confusion was stirred up as people often mistake these laser markings to be signs of clarity treatments. In view of irrational fear by the buying public, GIA (Gemological Institute of America) changed the terminology used to indicate the presence of such laser markings.

This is done to set a clear distinction between diamonds that had undergone deliberate laser clarity treatments and the “residual” effects of using lasers to cut diamonds.

A Manufacturing Remnant Comment Isn’t Clarity Enhancement

For people who are worried about buying a clarity enhanced diamond by accident, rest assure that any diamond graded by GIA has passed all the necessary tests to identify such treatments. Note that GIA will not issue a lab report for diamonds that had undergone non-permanent enhancement processes like fracture filling.

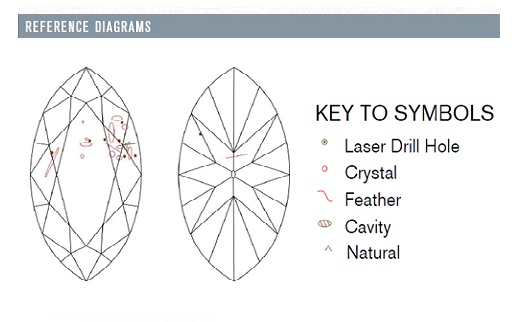

In the case of permanent clarity enhancements performed via laser drilling, these treatments will be disclosed in the grading report as laser drill holes. Here’s an example of a clarity reference diagram indicating such a diamond.

This diagram is extracted from GIA grading report #1142498546

What’s a Manufacturing Remnant? Is it Serious?

In contrast, the manufacturing remnant noted in newer GIA reports is usually caused by residual markings of the laser cutting process. You can imagine this as a saw blade (made of laser) that cleaves through a rough stone.

In the process, it leaves behind mechanical markings (or manufacturing remnants) which can take several forms such as small blemishes on the diamond’s surface or internal damage in the crystalline structure.

Manufacturing remnants in the context of diamond cutting and polishing highlights the importance of precision and accuracy in the jewelry industry. Scales play a vital role in ensuring that the right amount of pressure is applied during the cutting and polishing processes. Jewelers rely on scales to measure the precise weight of the diamond being worked on, as even a slight deviation can result in undesirable manufacturing remnants. By using scales, jewelers can maintain consistency and control in their craftsmanship, reducing the likelihood of excessive heat or pressure that can lead to visible blemishes or internal damage. To learn more about the significance of precise measurements in diamond cutting and polishing, visit reputable jewelry industry resources and educational platforms.

A manufacturing remnant could also refer to burn marks caused by excessive heat on the polishing wheel. Most of the time, these burn marks can rarely be seen with the naked eyes because they are very faint. In worst case scenarios, they show up as milky patches.

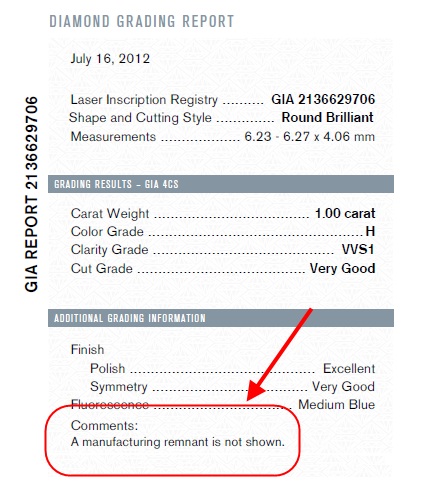

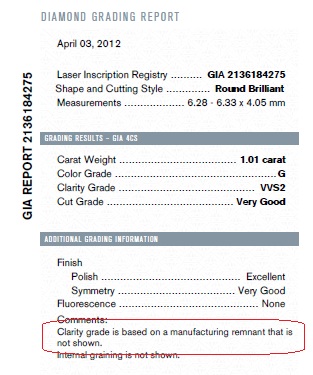

Here are 2 examples with the comment being noted in the lab report…

“A manufacturing remnant is not shown” – GIA grading report #2136629706

“Clarity grade is based on a manufacturing remnant is not shown” – GIA #2136184275

Mind you, these 2 examples are found in the top tier of GIA’s clarity grading scale – with ratings of VVS1 and VVS2 respectively. I can guarantee there’s no way the manufacturing remnants will be visible to your naked eye. In fact, they are so small that even a skilled gemologist would have difficulty in locating them with a 10X loupe.

The bottomline is, a manufacturing remnant is NOT the same as clarity enhancement.

I don’t think you need to worry about them and you can treat them just like any other types of inclusions. Hopefully, this article addresses the doubts you have with manufacturing remnants. If you are still concerned about it, drop me an email or leave a comment with a link to your grading report or diamond.

Related Articles

Leave A Comment

6 Comments

Thanks you for the website and advice you have given others. Now, you probably get this question all the time, but – how can I be sure that online diamond retailers such as Whiteflash are not cheating me?

I know that they will be sending me the AGS lab report, and that ACA diamonds come with the report number laser engraved, but what really prevents them from sending me a diamond that does NOT match up with the lab report, but which has been laser engraved with the correct report number anyway? How do I verify that the AGS lab report is legitimate and not fake?

I’ve read your Whiteflash reviews, including this one: https://beyond4cs.com/reviews/whiteflash/a-cut-above/

You captured mobile images of the ASET image to verify the light performance, but for other less knowledgeable consumers such as myself, how do I check the diamond? If I purchase a diamond with a ring, can I still get a lab in Singapore to examine the diamond (which has already been mounted) to check the laser engraved AGS number and overall quality of the diamond?

I really want to make my purchase from Whiteflash, but as you noted in your posts, it is a big leap of faith.

Thank you so much for hearing me out and sharing your insights and advice. It is very much appreciated!

First of all, no business (especially those with a reputation to protect) will put their entire reputation on stake just to rip you off or cheat a consumer for a few thousand dollars. It’s not worth it even if you are talking about a $50k transaction. Vendors like White Flash are rock solid and reliable. The trust that they had built is worth well more than that and to have an angry client suing or running off to tell the world of a bad experience.

Read this article: https://beyond4cs.com/clarity/how-to-use-a-10x-jewelry-loupe/ and use the technique to check the diamond for matching inclusions/laser inscriptions. Or bring the diamond to an appraiser for a check. You are covered with a money back period to do all the inspections you like.

You could either buy your own set of idealscope/ASET scope (will cost you about $100USD) and do the check yourself for performance. I will reiterate, what White Flash shows on their listing page is accurate. If you need help with assessing the diamond, let me know which stones you are looking at.

Thanks alot Paul. That makes alot of sense and I do feel more assured now.

I’m looking for a Whiteflash diamond with the following parameters:

• A Cut Above ideal cut round diamond

• 1.2ct to 1.5ct size (preferably closer to 1.2ct)

• Color of at least F

• Clarity of at least VS1

I’ve been spending the past few days going through the articles you wrote on Beyond4Cs again on how to choose the best diamond. I’ve narrowed my choice to these 5 diamonds, but I am really having some difficulty choosing the best from these 5.

https://www.whiteflash.com/loose-diamonds/compare.aspx?idnos=3947686,3947688,3934301,3947691,3947694

Can I please get your advice as to which diamond you think has the best light performance? I am thinking of either AGS-104097078029 or AGS-104097624019. Would you agree?

If you happen to spot another diamond that is better outside these 5, I would be most grateful if you could please let me know as well.

Thank you so much for your advice! I sincerely appreciate it. Also, Happy Chinese New Year to you and your loved ones, wishing you a blessed and prosperous 2018!

To me, this is really straightforward as I take on a practical approach in buying diamonds. To get the best value for money, these are the 2 stones I would pick.

https://www.whiteflash.com/loose-diamonds/round-cut-loose-diamond-3947691.htm

https://www.whiteflash.com/loose-diamonds/round-cut-loose-diamond-3947694.htm

But really, you can’t go wrong with any of the 5. The high color grade is a matter of personal preferences. I would go with an F because I know that it faces up exactly like an E diamond and being able to save some money on that is a great thing.

I’m still confused by laser drill holes and remnant defects. If both are created by man made causes during the polishing process, what’s the difference between them?

A drill hole actually penetrates deep into the diamond’s body for the purpose of creating a pathway to an inclusion that is later bleached out. A manufacturing remnant is non-penetrative and typically found on the surface of the diamond. The intent is completely different and the “damage” done to the diamond is on a different level as well. I hope this makes sense.