How Are Diamonds Cut And Polished From Roughs?

Diamond cutting is the process that takes a rough diamond and changes it into a shaped and beautiful gem. The process must be undertaken by a professional with expert knowledge, equipment and tools for the job since every single decision made will affect the outcome of profitability.

So, what are the main considerations a cutter take into account when planning to cut a diamond? The first choice to make is to decide on the shape itself; round, oval, pear etc. And secondly, the proportioning of facets and quality of the cut (i.e. symmetry and polish) are planned with computer simulations.

In this article, I’ll be showing you what really goes on behind the scenes when a plain looking rough gets transformed into a bright, shiny gem.

Did you know that almost 80% of all rough diamonds pass through different hands in the city of Antwerp, Belgium? Out of these rough stones that are traded, 92% of them will end up in India and are actually cut in the city of Surat.

This means whatever diamond you are buying in the market today has more than likely traveled around the entire globe before it reaches your hands!

The Diamond Cutting And Polishing Process

Since diamonds are made of the hardest material in the world, only a diamond can be used to mechanically cut another diamond. Lasers are another alternative but their uses are largely limited to the cleaving and bruting purposes. Usually, the tools used in the workshop consist of diamond-bladed edges or discs that are lined in diamond dust.

The actual process of how diamonds are cut and polished can be broken down into five steps: planning, cleaving, bruting, polishing and inspecting.

Stage 1: Planning a Rough Diamond

Planning to cut a rough stone is one of the most important things to get right. While it can be a time consuming process, this is also the step that determines the final value of the finished products.

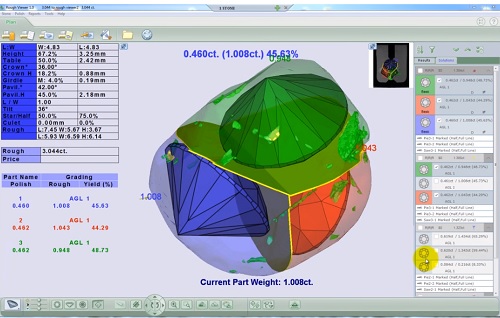

In the planning stages, the cutter will figure out the best possible shapes of the diamond in order to minimize waste and maximize the yield of the rough stone. Typically, the rough stone is mapped with a Sarin machine to generate accurate measurements.

With this data, a computer software is then used to formulate 3D models that will show the cutter the best ways to optimize the rough.

Stage 2: Cleaving/Sawing a Rough Diamond

Copper disc embedded with diamond dust sawing a rough diamond.

The cleaving process is the part that involves splitting the rough into separate pieces. This will then allow the cutter to work on the pieces separately and also to utilize the rough fully.

Mechanical sawing can also be undertaken at this stage. In the case of oddly shaped roughs, the sawing process can also be undertaken with contactless cutting tools like lasers.

Stage 3: Mechanical Bruting to “Round” the Roughs

Mechanical bruting to form the outline of the polished diamond.

After the diamond is split, bruting is then performed to make the separated rough stones round. This is process is also known as girdling. What happens here is that two diamonds are placed on a spinning axle across each other. They will then turn in opposite directions and grind against each other to create a rough girdle finish.

Stage 4: Polishing the Diamond Facets

A rough diamond being facetted on a polishing wheel.

Once the rounded shape of the rough is formed, the next stage is to create and form the facets of the diamond. The cutter places the rough on a rotating arm and uses a spinning wheel to polish the rough. This creates the smooth and reflective facets on the diamond.

Interestingly, this polishing procedure is further divided into 2 steps: blocking and brillianteering.

In the blocking process, 8 pavilion mains, 8 crowns, 1 culet and 1 table facet are added to make a single cut stone. The importance of this step is to create a template for the next stage.

The brillianteer will then finish up the job by adding in the remaining facets and bringing it to a total of 57 facets. He holds great responsibility as the fire and brilliance of the diamond is determined at this stage.

Stage 5: Inspecting the Polished Diamond (Quality Control)

The last stage is the inspection process. This is where the diamond is checked to make sure it meets the specifications set out by the manufacturer. If need be, the stone would be sent back to the polishers for some touching up if it didn’t meet the quality control standards.

Diamond Manufacturing Process From Rough to Polished – Short Video

The Grading Report For Quality Assurance

Once a diamond has been cut, they are usually sent to the gemological labs for a grading report to be obtained. This will not only increase the value of the diamond but will also help people buy the stone with confidence.

Take note: When buying online or via physical stores, AVOID any stones that don’t come with a reliable grading report from AGS or GIA.

Chances are, the diamond’s quality is really poor and the jeweler is banking on selling it to an unwary customer. You see, selling an uncertified diamond turns in a better profit as compared to sending the stone for grading only for it to return with a damning report.

Interested in Learning the Art of Diamond Cutting?

If you are interested in picking up the craft or want to enroll yourself in a diamond cutting school, check out the following websites for more details.

American Institute of Diamond Cutting – Besides offering courses, they also sell useful textbooks for references on rough and colored diamonds.

Corlia Roberts Diamond Education College – Based in South Africa, they are one of the most recognized schools in the continent. Upon graduating with a certificate, the knowledge you had acquired will help you open doors to careers in the industry.

Harry Oppenheimer Diamond Training School – This institute is a joint project between De Beers and the Diamond Foundation of South Africa, Johannesburg. The courses offered prepare you for real life diamond cutting and skillsets to tackle problems in the industry.

Related Articles

Leave A Comment

16 Comments

I am a young man of 28 years living in Botswana and interested in opening up a company which deals with the cutting and polishing of diamond. How do they cut diamonds? So i am kindly asking for information on machinery that are used and where there can be procured.

i am a young motswana of 23 years living in botswana and interested in opening a company which deals with jewelry and diamond recycling. i want to know of any materials used for this recycling process and where can i acquire them.

You are at the wrong place. This is not an industry forum or website for wannabe business people. It’s for consumers.

hello Paul,

I want to buy some raw diamonds from a trusted site and learn how to cut diamonds by hand. Can I consider them graded or their value comes only after the polishing? I’m making metal non expensive jewelry and I think they look very nice.

thank you very much

If you are asking me such questions, you better be careful where you thread because you clearly aren’t sure of the basics of the industry for someone in the business. You will lose your shirt and alot of money if you don’t know what you are doing.

Hello

Can you please provide me with details of `Rough Diamond Cutting and Polishing’ service providers in London, UK; New York. USA. Dubai, UAE and India.

Thank you

You are at the wrong website.

I had no idea diamond cutting was such an intensive process! I can see now why it costs so much to get a diamond cut.

Do you think diamond cutting would be a lucrative craft to pursue? From what I’ve read, cutting a diamond costs upwards of $400 per carat, which sounds great if you’re the diamond cutter, but I’m also not aware of any costs involved in actually cutting the diamond.

It depends on the type of diamonds you are working with if you are a cutter. $400 per carat is the price for slightly higher end goods (e.g. bigger carat). There are risks involved with cutting stones as well because mistakes are costly and there’s a learning curve. Beyond the limited knowledge I have about pursuing polishing as a career, I’m afraid I am of not much help here.

Hi Paul, this information has helped me to understand the Process a lot better and what is used to cut diamonds. I have started an internship at a diamond cutting company, and prior to going for my interview read through this information and it helped a lot for my first step into the industry. keep up the good work.

Hi Paul, I wish to follow a career in diamonds polishing but i am a bit skeptical as i don’t know how much machines to process that will cost me and which school is the best in this regard please advise me.

You should start here: https://www.diamondtrainingschool.co.za/

Hi Paul,

Great article, I appreciate your insight. It is always interesting to learn about new industries. I’m not sure if you have insight into this, but I am interested in diamonds in relation to an engagement ring. Option 1 is simply going into the local jeweler and buying what they have behind the counter. I am wondering if it might be cheaper or a better value to buy a rough diamond, send it to a cutter, and then send it to a jeweler to set into a band? Appreciate any information you have.

You are much better off buying a diamond that’s already been polished with a GIA or AGS certificate. That is going to be MUCH cheaper and give you a better quality diamond on top of reducing hassle.

How’s it Paul,

I know nothing very little about diamonds and have been searching the web on the early posseses in which diamonds are to become cut. You see I believe I came across some diamonds I’ve found in a house that my boss owns and rents out. This was an older lady that had pass on. Anyhow, these stones I’ve found are rounder and have little tits on one side. And had a note saying pearls $1900. She had glued them to a fake plastic leaf and the shoved into a vase with a large base but tiny opening. I looked through this opening with 5ue flashlight on my phone and noticed something was inside. Essentially, the only way to get to what was inside was to break it. My question being do cutters round out the diamond before cutting it. These are round and will cut glass. Something round and still able to cut glass has me wondering. Thanks

There are alot of gemstones that can cut glass easily and the most common simulant of all is cubic zirconium. These cost a few cents to the pennies and the best way to be sure is just to bring them to a jeweler to check out what you have. Otherwise, you can always buy a diamond tester (a good one will cost about $200) and DIY.