What is a Sarin Scan And How Much Value Does It Provide?

*Update: Sarin Technologies was officially renamed to Sarine Technologies in 2014.

Sarine’s DiaScan S+ system.

In diamond cutting and grading assessment, the angle and proportioning of every single diamond facet matters. In fact, each measurement down to the nearest tenth of a degree constitutes to the diamond’s light performance.

So, when we are talking about dimensions that are so precise, how do we ensure accurate and repeatable measurements?

The answer to this is through the use of high-tech machines. Smart as we are, there’s no way humans can perform consistent and accurate measurements by hand without using specialized equipment. And in the jewelry industry, time is also money.

To meet demands for fast and reliable methods of mapping diamonds, Sarine Technologies (previously know as Sarin) has developed a series of sophisticated optical technologies and measurement systems. Today, these state-of-the-art equipment are used in grading laboratories as well as production factories.

From an engineering standpoint, the concept behind their elegant solution is very impressive. Lasers are used for mapping out a gemstone’s proportions with high speed and precision. Using moving actuators, delicate motors which control signal detection and a sensitive docking stage, the accuracy of measurements can be kept within 20 microns.

To put things into perspective, the accuracy of Sarine’s measurements is more precise than the thickness of a human hair (60 microns).

Did You Know That ALL Major Grading Labs Utilize Sarine Machines?

Sarine products find their place in the diamond industry all over the world.

Almost every respectable gemology lab owns a Sarine machine that can be used to capture data for gemological purposes. Well-known labs like GIA, AGS, EGL and IGI all use similar models to automate measurements of a diamond which are then subjected to further analysis.

Uses of Sarine Machines in Diamond Manufacturing

In the manufacturing plant where rough diamonds are sorted and queued for polishing, the Sarine machine is a mandatory tool for planning and optimizing yield.

Before Sarine machines were introduced, the way rough crystals were handled in the planning process was vastly different. Very often, rough diamonds will have a frosted layer of skin which obstructs the view of the stone’s interior.

“Windows” were often polished on the rough crystal in order to allow cutters to peek within the diamond’s body for accurate assessment and planning.

The use of Sarine’s latest technology has changed all that. Windows would no longer be required in order to examine the stone internally. With the accurate 3D mapping of inclusions, human errors were also significantly reduced during the cutting process.

Sarine for Retail And Dealer Applications

Besides being used in upstream manufacturing processes, Sarine systems have also gained widespread popularity for downstream businesses like dealers and wholesalers. Also, for businesses that offer re-cutting services to consumers, Sarine is an indispensable tool.

While it isn’t widely used in retail stores yet, there are certain benefits of having a Sarine machine in-store. View the following video for more details.

When wholesalers do business with another supplier, Sarine machines like the DiaMension HD can also be used to evaluate a diamond’s symmetry and proportions. A quick scan of a diamond may reveal subtle issues like facets misalignment, point to point facet junctions and other symmetry related problems which can ultimately help them make purchasing decisions.

For a Consumer, What Does the Sarine Report Tell You?

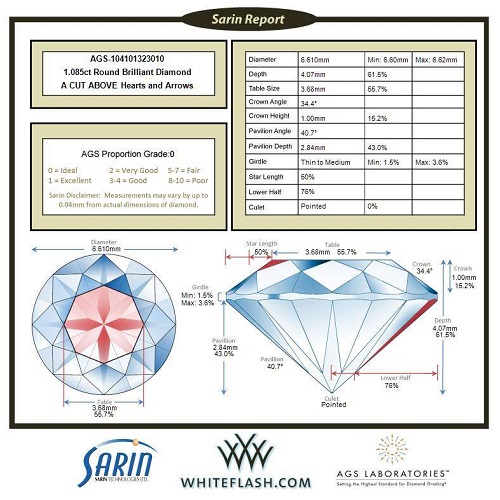

Sample Sarine report for a round cut diamond from a listing at White Flash.

Bear in mind that a Sarine report is not a replacement for a lab grading report.

Interestingly, it wasn’t until recently that the major gem labs started to include details of the cut quality and condition of the diamond in their grading certificates. In the past, a scan performed by tools like the Dia Mension or Dia Pro would be sufficient to generate a report that is accepted by people in the trade.

Today, grading labs like GIA and AGS already provide averaged measurements and proportions performed by Sarine in their lab reports. As a consumer, you can now find the measured values conveniently displayed in the form of a proportions diagram.

And because of this, it diminishes the usefulness of a Sarine report because of the overlapping information it provides. This brings us to the next question, when would a Sarine scan be useful to you since you can already find similar details in a lab certificate? Do you still need to go so far as to request a Sarine report from your dealer?

I will discuss that in more details on the next page…

Related Articles

Leave A Comment

4 Comments

I’ve recently came across a report on the Sarine Diamond Journey and was intrigued to find out how receptive consumers are to the report. Would that materially help jewelry businesses make more money?

Thank you for your time! I’m a fellow Singaporean too.

The Sarine Diamond Journey report is essentially a marketing tool to provide customers with more information about the mine to a polished diamond ring. It was released as a traceability report to give consumers more details of what they are buying. Fundamentally, there’s no value add to a customer who is looking for technical information. So far, I know Brilliant Rose is one of the brands they work with and this is a line of diamonds that can be found in some Singapore based jewelry stores.

As to how much value and conversions it can lead to, I’m not too sure about how receptive consumers are to this marketing report. It’s not a document that I look at if I were buying a diamond and I think its more bells and whistles than anything else. I want to buy a diamond that is cut for light performance and sparkle. The Sarine Diamond Journey report doesn’t change how well cut the diamond is nor does it offer me any tangible useful info to base my decision making on.

I have a question to ask, if I buy sardine Diascan S+ system for diamond polish grading purpose, can I use for Rough diamond as well? Or I should buy separately?

Regards,

Binyamin Asher

I am not sure what you mean when you are referring to using for rough diamonds. But if you are using it to evaluate semi-polished diamonds that are work-in-progress, the Diascan should work fine for evaluation purposes. You should direct any technical questions directly to Sarine Technologies and tell them your exact use case.